In this industrial 4.0 era, the global liquid filtration market will grow from 2.1 USD in 2019 to 2.9 billion USD by 2024 at a CAGR of 6.5 %. Rapid urbanization, industrialization, and environmental concerns are increasing the need for liquid filters worldwide. And for the food, chemical, and other industries, vertical leaf filter, and others are now in high demand. Only the experienced manufacturers provide excellent filters for practical and economic filtering along with reliability and durability.

Benefits of vertical leaf filters

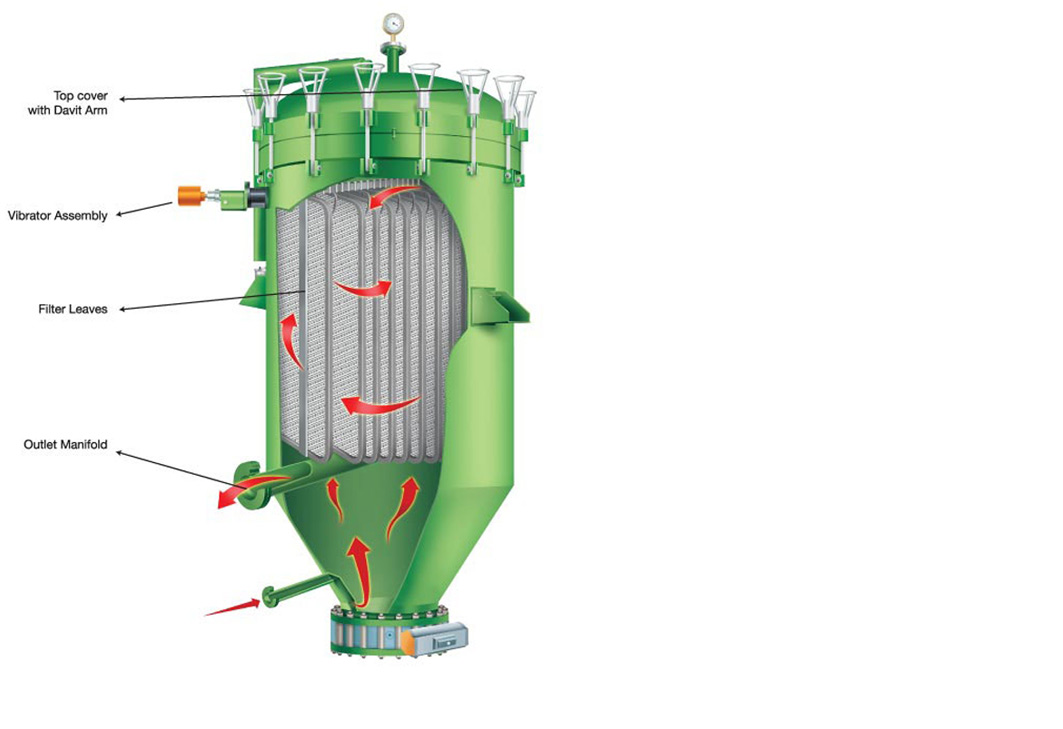

Vertical leaf filters are ideal for continuous filtration processes, even for many batches. They find applications in many industrial uses from vegetable oils to pharmaceuticals and from food, beverages, and biochemical to biofuels, and brine solutions. They have multiple filters leaves vertically positioned in both horizontal and vertical tanks, and the fluid gets cleared by flowing through both the sides of the leaves. As the leaves are a vital part of these filters, only excellent manufacturers will provide the best quality leaves for many of their benefits that including, among others.

- Suits best for minimum floor space for the requirement of the huge filtration work area

- Have hermetic sealing to offer more filtration rate

- Design enables PLC automation and the automated discharge of the filtered cake either as dry or thickened slurry.

- Ideal for volatile liquids without the need for vacuums

- Best in places of environmental concerns due to toxic filtered cakes that need a particular discharge mechanism

- Offers filtration areas up to 125 M 2 in a single housing with minimum pressure drops across the leaves

- Best for high filtrate clarity requirements and in for handling brine solutions that need elevated temperatures

- Ideal for filtrations that need less time and low maintenance costs with high-temperature O-rings and sealing arrangement

- Best for fluids with high solid contents, especially in the food and beverage industry

Simple candle filters for a variety of applications

Candle filters are simple devices used for residential, commercial, and industrial uses that include oil, water, bio, and hot gas filtration. They come as air or liquid filter product types that have sintered, perforated, pleated, and others. These filters remove suspended materials, bacteria, and turbidity from air and liquid. The most common candle filters are the honeycomb-shaped ceramic candle filters, and their market share has exceeded 1 billion USD in 2019 and is growing at a CAGR of 14 %. The candle filter applications include many industries that include, among others.

- Food & beverages

- Oils including edible and other oils

- Pharmaceuticals

- Chemicals

- Power

- Mining & metallurgy

Benefits of candle filters

Unlike other filters, residual substantial cake increases as the filter process continues to hinder filtering. But in candle filters, the unwanted solid contents are removed from the slurry as the fluid passes through it. Many other benefits include

- Effective in removing bacterial, helminths, turbidity, and protozoa from water

- Removing viruses, iron, taste, smell, the color of water

- Providing think-cake pressure filtration, drying, slurry, washing cake, heel filtration, and also automatic discharge

- Available in many types, capacities, sizes, and others for effective filtration of solid waste including hazardous substances

Mectech is one of the leading liquid filter manufacturers globally for the past many decades and is the best candle filter exporter from India.

Hi, I am Adam Smith, Admin Of TechSketcher, Creative blogger and Digital Marketer.