As machine learning (ML) becomes more advanced, its potential applications in mechanical engineering grow. ML can be used to develop new materials, optimize designs, and streamline manufacturing processes. The benefits of using ML in mechanical engineering are numerous. Keep reading to learn more.

Machine learning can improve the accuracy of simulations through data-driven models.

It is a process of data-driven modeling that can improve the accuracy of simulations. In mechanical engineering, this could mean improving predictions of fluid flow and turbulence, heat transfer, stress and vibration, or other physical phenomena. With more accurate simulations, engineers can optimize designs for everything from cars and aircraft to power plants and wind turbines. Machine learning works by “training” a computer model with a large set of data. The model then uses this data to predict the behavior of similar systems in the future. For example, if you wanted to predict the weather, you would need to train your model with past weather data. This approach is much more effective than hand-crafting models based on intuition or experience alone. It can be used in analytics and data strategy. Analytics strategy is a plan of action that companies use to collect and analyze data in order to make better business decisions. ML is a type of artificial intelligence that allows computers to learn from data without being programmed. And it can be used to improve the design of products, predict failure rates, and optimize manufacturing processes. By analyzing large data sets, ML can find patterns and correlations that would be missed by humans. This information can then be used to improve models and analytics strategies in the future. In this sense, ML can be seen as an analytics investment.

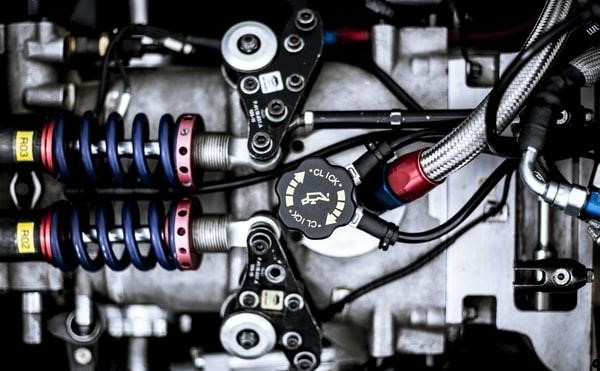

ML can help improve predictions about product performance.

The purpose of ML is to make predictions or decisions that are too difficult for humans to do manually. It can help improve the accuracy of predictions about product performance by using large amounts of data and algorithms to find patterns in that data. This allows manufacturers to better understand how engineering products will perform under different conditions and make more accurate predictions about when products will fail. Additionally, ML can also be used to optimize products for specific applications or customers. By understanding the needs and preferences of individual customers, manufacturers can create products that are more likely to meet their needs. If you’re interested in obtaining a master’s degree in mechanical engineering to work with ML, you can obtain an online mechanical engineering masters degree to advance your professional development. In the mechanical engineering sector, ML helps to improve product performance. And enrolling in an online program allows students to learn more about the latest technologies.

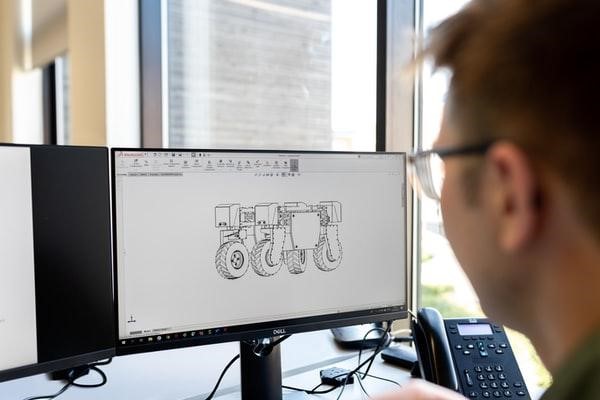

Algorithms improve designs and processes in mechanical engineering.

This is done by having the machine learn how to recognize patterns in data and then use that information to improve the design or process. For example, an algorithm could be used to optimize the shape of a part that is being manufactured. The algorithm would be given data on how well different shapes perform under various conditions, and it would then learn which shapes are best suited for specific applications. As a result, the manufacturing process could be streamlined so that parts are designed and produced more efficiently. Additionally, it can also be used to predict failure modes in mechanical systems. By analyzing data from past failures, the algorithm can develop models of how components are likely to fail. This information can then be used to prevent failures from occurring and improve overall system reliability.

Overall, the benefits of using ML in mechanical engineering are vast. It can help improve system performance and efficiency, optimize designs, and predict future failures. Additionally, it can reduce manufacturing costs and improve product quality.

Hi, I am Adam Smith, Admin Of TechSketcher, Creative blogger and Digital Marketer.