Adding threaded surfaces to a workpiece is one of the most common tasks we perform as machinists. Most shops used to perform this delicate process by means of taps and dies. While the method used to be considered efficient, new technologies have proven to yield better, more accurate, and faster results.

This is the case with CNC machining and thread milling. Thread milling with solid carbide tools has helped solve many of the problems encountered when creating threads with taps and dies. For example, tapping makes chip evacuation difficult as it limits escape routes to flutes that can get clogged. Another problem was chip compaction when threading blind holes, as chips that can´t escape upwards get trapped at the bottom. Moreover, tool failure during tapping usually means having to rescue the bit inside the piece and, in many cases, it also means completely scrapping costly pieces and material.

Specially designed carbide thread mills can machine internal and external threads with ease without worrying much about chip evacuation or having to scrap parts due to tool failure. This makes them extremely versatile and efficient as, depending on your choice, you can use the same tool for several diameters and thread pitches. Due to the nature of carbide, these tools can be operated at high speeds and temperatures, speeding up the process of part or pipe threading and allowing shops to have a higher stack of finished pieces at the end of the shift.

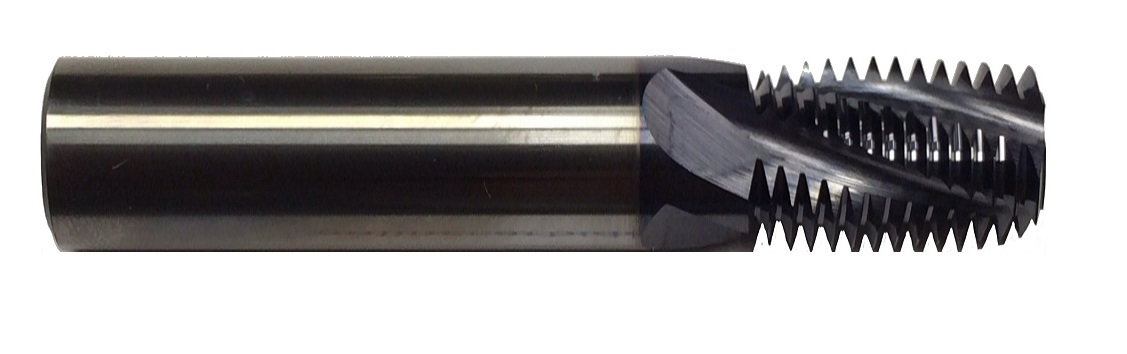

For operations that require uniformity, such as standardized NPT pipe threading, thread milling with solid carbide full form cutters can yield incredible results. Full-form thread mills are designed with a series of teeth or cutting points along the length of cut. The separation between these cutting points is based on the pitch the tool is designed to cut. This means that the cut is able to cut a full threaded surface in a single pass, creating uniform and perfectly finished threads very quickly.

For operations that require more versatility, such as creating several threaded surfaces with different pitches, single-pitch thread mills are the best option for expanding your tool catalog. Their design is different from that of full-form cutters in that they only have a single cutting point at the tip. It means that the tool must trace along the length of the surface to complete the cut. The process is slower than having it done with full-form cutters, but it allows the machinist to modify the pitch, even mid-cut, making it possible to perform several operations with only one tool. They are also better suited for performing delicate cuts on thin-walled components or difficult angles and threaded surfaces on overhang sections.

When choosing your thread-cutting tools, make sure you buy from high-performance tool makers. Carbide is the preferred material for thread mills given its increased hardness, its sharpness retention, and accuracy. Carbide yields better surface finishes, and enhanced durability, allowing shops to reliably create high-quality threads faster.

But not all suppliers are the same. This means that you need to get your tools from trusted suppliers and manufacturers that have your best interest in mind. Online Carbide is an American cutting tool manufacturer that offers a wide range of high-end carbide thread mills for workshops that need to increase productivity while keeping costs down. Additionally, Online Carbide designs and crafts carbide tools for a wide range of applications such ad spot drilling, end milling, chamfering, and much more. Visit www.onlinecarbide.com today and start taking advantage of their competitive manufacturer direct prices and superb quality.

For more information about Buy Carbide Drills and Variable End Mill Please visit: Online Carbide.

Hi, I am Adam Smith, Admin Of TechSketcher, Creative blogger and Digital Marketer.