In so many industries, it seems to be the case that quality falls by the wayside as newer, cost-effective processes turn the tides. Cheaper goods can be made more quickly and sold at similar margins, improving the seller’s bottom line but adversely affecting all the infrastructure that’s touched by their products.

Think about cell phones. It was the case in recent memory that certain flip phones were as bombproof as a brick. You could drop them off a dam, retrieve them, dry them out, and fire them up. Today’s smartphones are much more fragile.

This is the case in many industries, but it is not the standard for all manufacturers. One, in the commercial plumbing industry particularly, is defying that trend.

For Leonard Valve Company, quality is baked into everything they do, and it has been for over 100 years.

Quality Isn’t a Lost Art…

To the engineers at Leonard Valve Company, quality is not a lost art. To them, it is evident in everything they create on a daily basis.

Leonard produces a wide range of valves, including but not limited to digital mixers, emergency systems, individual shower valves, specialty items, and much more.

In addition to being made from high-quality raw materials and components, Leonard Valves are compliant with five major standards for mixing hot and cold water.

ASSE 1016 is a standard that applies to shower and tub valves and involves the use of an Automatic Compensating Valve to control water temperature, reducing the risk of thermal shock or scalding. This standard requires the valve to shut down to less than .5GPM on cold water loss within 5 seconds, preventing the output temperature from exceeding 120℉.

ASSE 1017 is a standard applicable to temperature-actuated mixing valves installed at the hot water source. While these are intended to control water temperature at the source, they should be supported by an additional valve at the point of use.

ASSE 1069 applies to valves intended to regulate water temperature supplied to multiple fixtures such as “gang showers.” They are not intended for individual showers or tubs, and are instead used to regulate final outlet temperature to multiple devices.

ASSE 1070 applies primarily to fixtures such as sinks, toilets, and tubs, also with the intention of preventing the risk of scalding. Though these valves are intended to temper the supply of water to these fixtures, they can be further regulated by the downstream introduction of additional cold water. They are not intended to protect against thermal shock.

ASSE 1071 applies to Temperature Actuated Mixing Valves for Plumbed Emergency Equipment, such as eyewash stations, drench showers, and other such fixtures. These crucial valves allow for specified by pass of both hot and cold water, upon the failure of the other. These must be installed between the heat source and the fixture in order to be operable and effective.

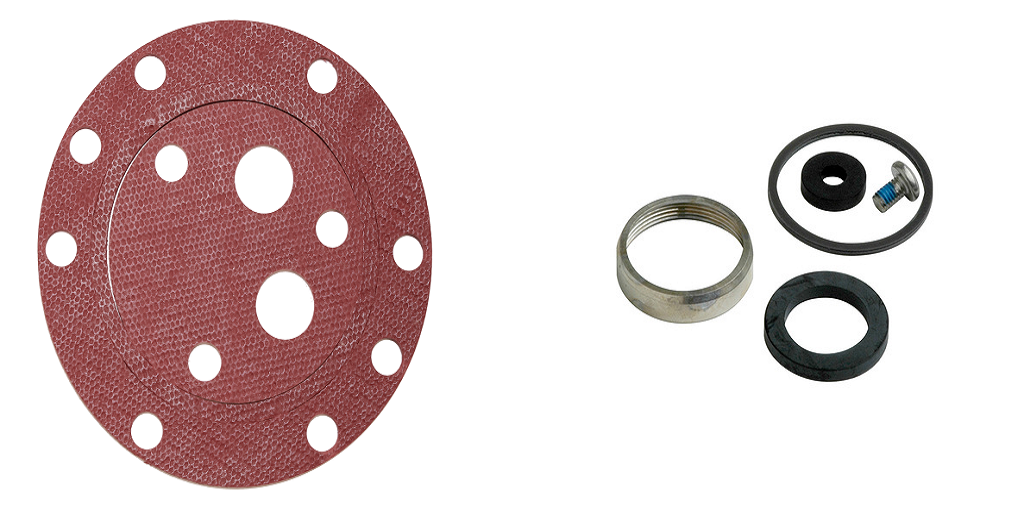

But You May Eventually Need a Leonard Valve Repair Kit: Where To Find It

In addition to rigorous observation of and adherence to these standards, age will wreak havoc on plumbing and you still need to be prepared with a supplier that can keep you prepared with the Leonard Valves and repair kits you need to fix leaking or faulty valves.

Over time, use, corrosion, hard water scale, and other factors can cause valves to fail, in which case replacing or repairing them becomes a matter of personal safety, as these devices protect users from the risks of scald and thermal shock.

Quality Plumbing Supply offers a wide range of Leonard Valve kits, Leonard valve repair kits, and rebuild kits, as well as tools and countless other commercial plumbing parts and fixtures. If you have any questions about what parts you need to make repairs (or just need a fair price) visit their website today or get in touch with them at 1-833-251-4591.

For more information about Commercial Plumbing Supply and Thermostatic Cartridges Please Visit: Quality Plumbing Supply

Hi, I am Adam Smith, Admin Of TechSketcher, Creative blogger and Digital Marketer.