We more or less are aware of the fact that an extensive range of heaters and heating applications are used across different industries across the globe. The majority of us, however, may not be aware of what exactly is industrial process heating and what important functions it serves. Industrial heaters are extensively used in a wide variety of industries operating in sectors like plastic, food processing, oil and gas, and chemical industry among others for specific processes.

There are five types of such heaters and we shall discuss them in the following section.

To put in simple terms, industrial process heating is when an industry makes use of heaters or other heat processing equipment like dryers, burners, ovens, etc. To generate heat which in turn is used to complete, facilitate or accelerate certain operations. Myriad industries ranging from food processing, oil and gas and chemical refining to asphalt among others make use of industrial heating elements during their manufacturing processes.

In a highly competitive business world, industries have to lay a premium on quality to attract new customers and retain existing ones. To achieve the high quality demanded of their products, organizations require adequate as well as controlled heat. This is where industrial heaters come in as they offer good control over process temperature. Also, in certain countries like Canada, Russia, and the USA among others. Which have a cold and harsh winter, electric heating assumes added significance. Excessive snowfall can halt production leading to precious wastage of resources. Electric heaters are used under such circumstances to melt snow and maintain the requisite temperature.

Immersion heaters

these heaters are generally used to heat liquids in large containers, vats, and tanks among other things. Immersion heaters use the direct heat transfer method to heat liquids in quick time. This type of heater is most appropriate for heating liquids that share vastly different properties. Available as flanged heaters, over the side heaters, circulation heaters, and screw plug heaters, immersion heaters entail very low maintenance costs.

Pipe heaters

as the name suggests, pipe heaters are designed to fit within 2 to 3 pipes. Unlike immersion heaters, pipe heaters do not remain in direct contact with the liquid that needs a heating. And as such are more appropriate for liquids that require low heat like making waxes, molasses, tar, etc.

Circulation heaters

a type of immersion heaters, are generally referred to as ‘in-line heaters’ and are available in a wide range of watt densities. You can choose a watt density depending upon your heating requirement.

Cartridge heaters– Cartridge heaters can carry thermocouples; this enables control of the heater’s temperature with greater accuracy.

Duct heaters

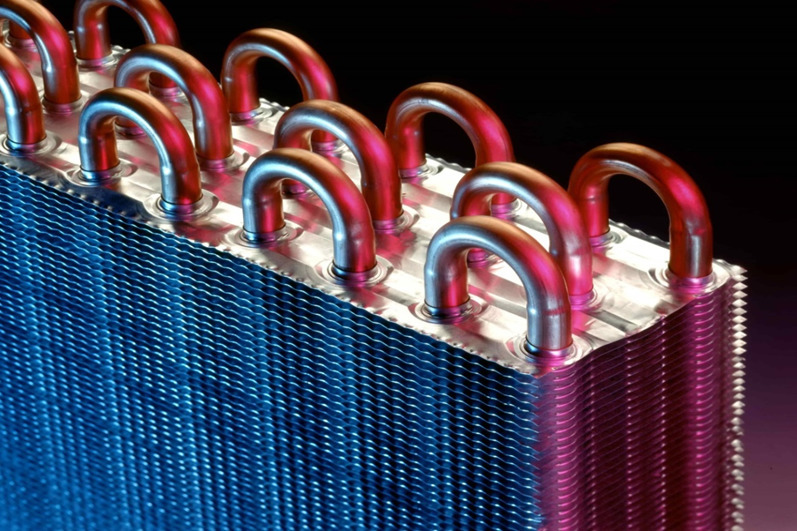

these heaters are used for ventilation systems or comfort heating. There are three basic types of duct heater, including tubular, open coil, and finned tubular.

High-quality manufacturers of industrial heaters and industrial heating elements can offer you superior quality heaters which seamlessly combine efficiency, affordability, and technological superiority.

Hi, I am Adam Smith, Admin Of TechSketcher, Creative blogger and Digital Marketer.